This is the MOST amazing piece of furniture I have ever seen. I was looking for a unique dining room table and searched several high end furniture websites for ideas. I contacted CVCF and they helped me create this masterpiece of Denali from an abstract concept to the final product. I was involved every step of the way. Pictures do not do this table the justice it deserves. I am beyond happy with this company from the communication, responsiveness, professionalism and of course, the finished product.

Jennifer Lombrano

We looked at a lot of River table websites and YouTube videos before contacting Chagrin Valley. They walked us through the design process and selection of the wood. Since we couldn’t be present for the wood selection we had to rely on them. We wanted the rivers in our area ( Colorado, Roaring Fork, Crystal, and Frying Pan) plus our house depicted. We also wanted our initials as part of the legs. All this was accomplished and I believe we got a beautiful table. The pics I have attached show the table, it’s legs, and the depiction of our house location.

Walter Weathers

Several months ago I found Chagrin Valley Custom Furniture online. I immediately fell in love with their work! I picked up the phone and called them; Shel answered the phone and after a long conversation he helped me narrow down what I was looking for. Shel then invited me to their facility to see how these custom masterpieces are made. That day I picked out the slabs for my river table. I also worked directly with Zach throughout the process. He was very prompt keeping me up to date on how the table was coming. My table was delivered today and it completely blew my expectations out of the water! The whole process was a world class experience! These are GREAT people to do business with, I would highly recommend them!!

Alex Smith

I'm amazed with the quality and craftsmanship of the boardroom river table CVCF made for us! The first time I talked to Sheldon, he asked me what style of table I was looking for and I told him that I wanted a river table 19' long and 5' wide. I also told him that I wanted it to be made in a steampunk style. He wasn't sure what that was, but boy, did he hit it out of the park with the river table he made for us. It has an industrial style base and an elegant top, and so I call it modern steampunk. It was created for shipment so that it arrived without any damage at all. It's absolutely beautiful! Shel, Zack and all the crew did a wonderful job and were great to work with!

Brendan Ganser

Working with this team of professionals and even more, so creative group, was an amazing experience from start to finish. I was very specific about what we wanted for our table and base. If I wasn't completely happy with what they sent, they tried again until I knew it was our dream table. It's a one of a kind experience for a one of a kind table!

I wanted to add they sent coasters for doing a review and they are spectacular. Like a lil version of our table. Wow just wow

Beth Ross

I COULD NOT be more thrilled with my resin table from Chagrin Valley Custom Furniture! I ABSOLUTELY LOVE the table and I receive SO many compliments from just about everyone that sees it. Sheldon was extremely helpful and personal from the 1st email/phone call. Eric, Sheldon and the entire team was so very helpful and kind! I have been researching and shopping for a resin table for almost 5 years. This custom experience was worth the time! Thank you to ALL!!

Kim Neppl

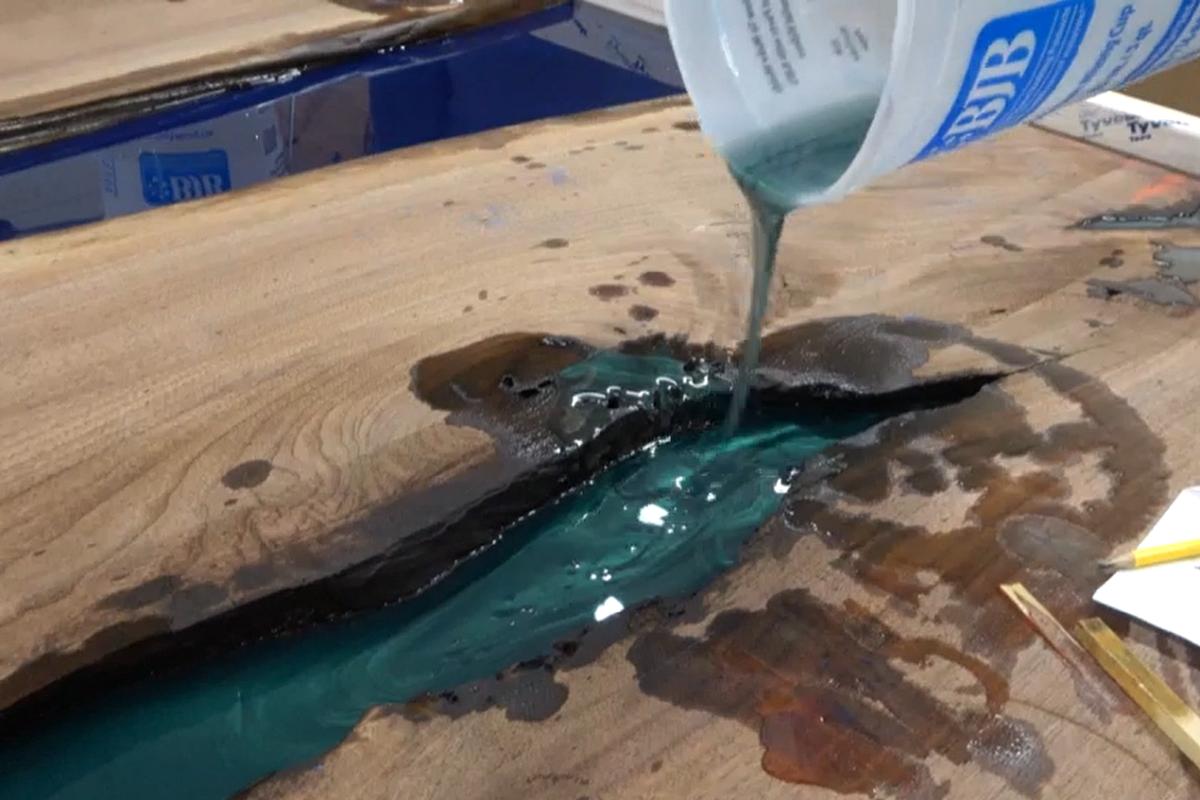

Every step of the process was great. Shel kept me updated on the process. I told them what I was looking for and they found exactly what I wanted. They called me on FaceTime to allow me to see the wood slab and mailed samples of the epoxy before I made the color selection. The end result is AMAZING! I cannot say enough good things about Chagrin Valley Custom Furniture! I would recommend this company!

Gregg Buck

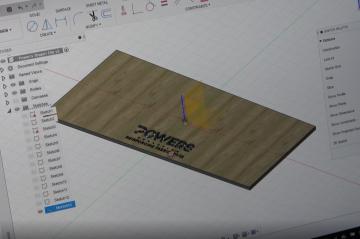

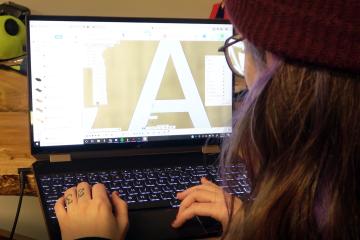

My wife and I just finished a dining room renovation project. Working with Zach and his team was an absolute pleasure. To call the folks at CVCF great woodworkers doesn't seem enough. More accurately, they are artists that use wood, epoxy, and technology to deliver custom works of art. Not only is the finished product first class, but the personalized care and top-notch customer service weave together to make a great story, which is a special part of the process. HIGHLY RECOMMEND!

Jonathan Epling

I ordered a custom coffee table and sideboard storage cabinet. The attention to detail and design far exceeded all expectations. I have pieces that will be passed down through generations. The staff is excellent to work and plan with. On both pieces and I now have a cohesive decor. Many, many thanks to Zach and the staff at Chagrin Valley Custom Furniture.

Gab D’Errico

We worked with Shel and Zach to design a beautiful custom countertop for a beverage center at our lake house in Texas. We received our delivery yesterday! It arrived ahead of our cabinet construction, so we don’t have completed photos yet. We opened the large well made crate just to confirm all went well with the shipping process. It is stunning, and the workmanship and finish is superb! Zach was a great listener, excellent with follow through, creativity and expertise. Even the FedEx delivery man was amazed. He said, “ I do some wood working, may I touch it to feel the smoothness of the transitions?” The character of the wood, and the finish are just perfect! We can’t wait to see the completed project soon! Thank you so much-we will consider this piece the art in the room! We will add photos when project is completed!

Marjo Richmond

Zach and Shel made me a lovely custom sit/stand desk with drawers and extra wide keyboard tray and matching side table. Everything was done perfectly to the measurements I asked for and Shel picked the prefect wood to match my style. These are perfect pieces that are completely custom.

Lindsey Fowler